Custom wrench material

1. Chrome vanadium steel: chemical symbol CR-V, it is the best quality steel.

2. Carbon steel: The quality is average, and there are more in circulation in the market.

How many kinds of wrenches are there?

1. Torx wrench

Both ends have working ends with hexagonal holes or twelve-angle holes, which are suitable for occasions where the working space is narrow and ordinary wrenches cannot be used.

1)Function: Torx end is usually used for the initial loosening and final tightening of screws (caps).

2)Size: 8*10, 10*12, 12*14, 14*17, 16*18, 17*19 (in MM).

3)Use: Push the joint between the torx wrench and the bolt with your left hand, keep the torx wrench and the bolt fully matched, and hold the other end of the torx wrench with your right hand and apply force.

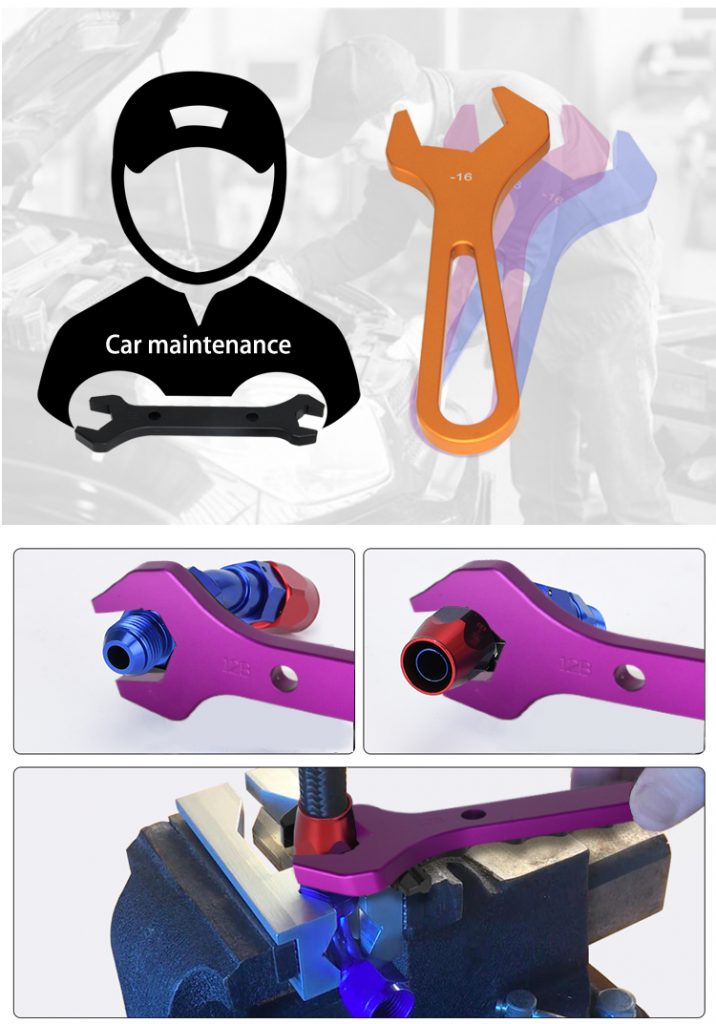

2. adjustable wrench

The adjustable wrench, whose opening width can be adjusted within a certain range, is a tool used to tighten and loosen nuts and bolts of different specifications.

1) Function: Used to rotate hexagonal or square head bolts, screws, nuts.

2) Size: 4″, 6″, 8″, 10″, corresponding to the opening 1.3, 1.93, 2.4, 3 cm.

3) Use: The wrench is not easy to open, it is easy to hurt people and round the bolt corners. The pulling force should be applied to the thicker side after opening to prevent the opening of the “eight” shape.

3. socket wrench

A wrench consisting of multiple sockets with hexagonal holes or twelve-angle holes and equipped with handles, extension rods and other accessories.

1) Function: suitable for screwing bolts or nuts with very narrow positions or deep recesses.

2) Size: three types of large, medium and small, common 6.3mm series, 10mm series and 12.5mm series.

3)Use: Put the sleeve on the square tenon of the matching handle, and hold the joint between the handle and the sleeve with your left hand, do not shake it, so as to prevent the sleeve from slipping out or damaging the edges and corners of the bolt and nut.

4. torque wrench

Also called torque wrench, torque wrench, torque adjustable wrench, torque can be set, and the torque is adjustable.

1)Function: Fixed torque wrenches must be used for the initial tightening and final tightening of bolts and large hexagonal high-strength bolts.

2)Size: 1-5N, 5-25N, 10-50N, 20-100N, 40-200N, 70-350N.

3)Use: First connect the wrench square tenon to the auxiliary accessories to ensure the connection. Before strengthening the torque, set the force value that needs to be reinforced, lock the locking device, and adjust the direction switch button to the direction of the force.

5. electric wrench

Wrenches powered by power sources or batteries are mainly divided into impact wrenches, torsion wrenches, fixed torque wrenches, angle wrenches, angle wrenches, hydraulic wrenches, torque wrenches, and cordless electric wrenches.

1)Function: Used in the steel structure installation industry, specializing in the installation of steel structure high-strength bolts.

2) Size: 600×420×150(mm).

3)Use: align the bolts and move the power switch. The electric fixed torque wrench can be used for initial tightening and final tightening. Its use is to adjust the torque first, and then tighten the bolts.

Custom wrench size

We can customize different sizes of wrenches as clients’ requirement.

Custom various of wrench